Materials

Materials

![]()

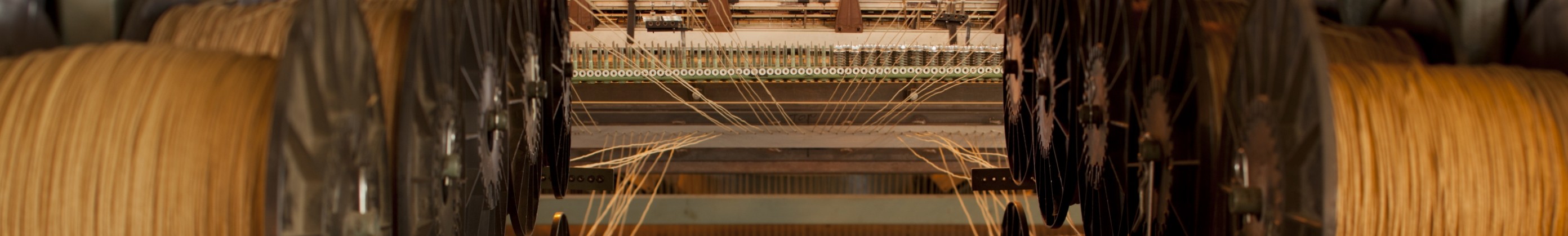

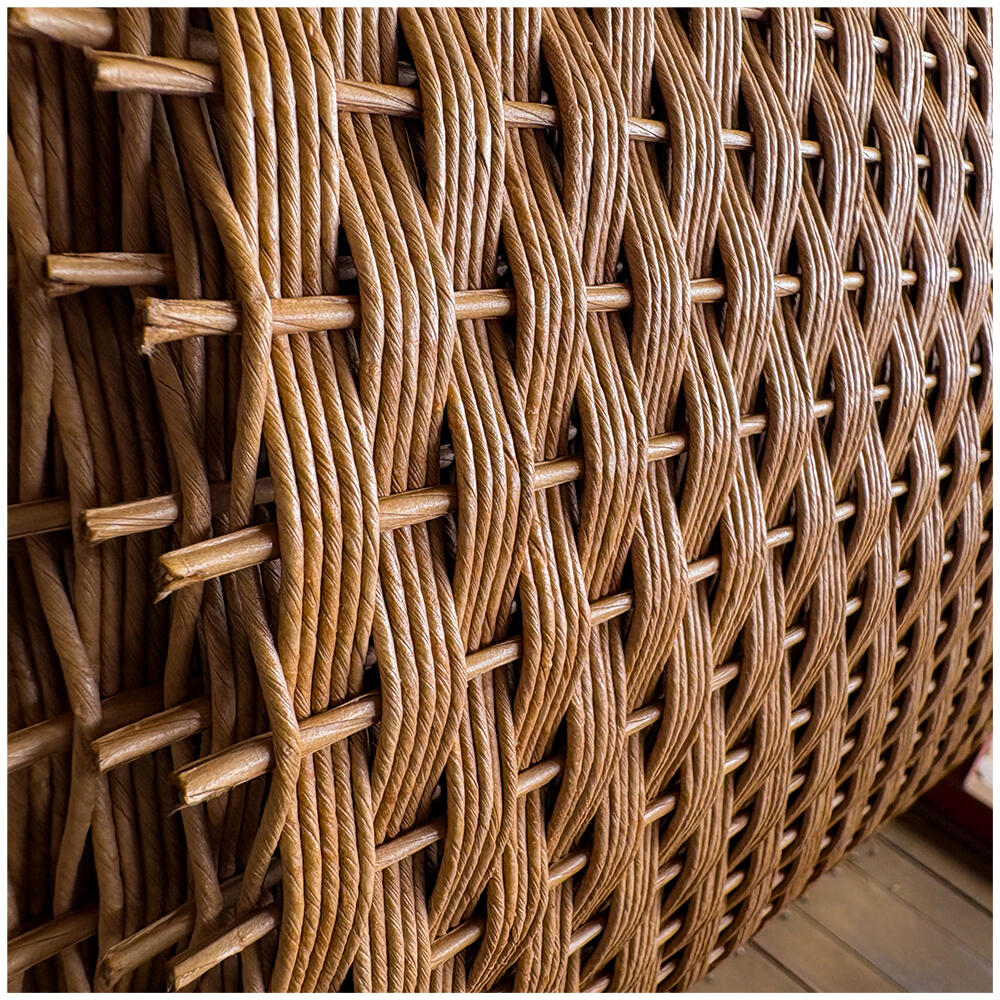

Lloyd Loom® furniture is still made in the same facility where this special process was first developed in 1917. Marshall Burns Lloyd created a process by which cellulose strands are woven into a wicker fabric as an alternative to the then popular method of wrapping cane around a frame.

Each hand-crafted piece of Lloyd Loom furniture made today uses the same process to create the loom fabric, though we've added advanced technologies over the last quarter century to produce a continuous strand that will not burr, crack, or peel, resulting in a consistently smooth weave.

|

Weaving |

Wrapping |

Finishing |

Lloyd Flanders offers a unique selection of vinyl all-weather wicker furnishings. From the classic romance of Mackinac, inspired by its island namesake, to the modern elegance of Mesa, our vinyl collections represent the best of traditional, transitional and contemporary decor.

|

Lloyd Flanders vinyl furniture is made with 100% virgin vinyl and has no added "fillers." |

Like our Lloyd Loom products, Lloyd Flanders vinyl furniture features welded all-aluminum frames that are corrosion-resistant and extremely durable. |

Our vinyl collections are available in a variety of distinctive colors, textures, and styles that are suited for all of today's outdoor living spaces. |

Lloyd Flanders offers teak tables that complement our Lloyd Loom and vinyl collections. Our premium teak wood is ideal for outdoor furniture because of its high oil content, inherent strength and tight grain. Teak is naturally resistant to decay and doesn't get brittle with age, adding to its capacity to withstand climate and environmental changes.

Lloyd Flanders uses only sustainably-grown and harvested FSC-certified Brazilian teak wood in our outdoor teak furniture.

|

|

|

|

Our premium outdoor cushion system redefines outdoor seating comfort. Our cushions feature exceptional comfort and resilience, inherently mildew/bacteria resistant components, and incorporate 1.5 density High Resilience California Fire Rated Foam.

Seat Cushions

|

Classic Premium Cushions |

Spring Coil Cushions Spring Coil cores are used in the deep seating cushions for the Alpine, Charisma, Escape, Frontier, Galloway, Pursuit, Summit, and Visions collections. |

Back Cushions

|

Formed Fill |

Blown Fill |

Lloyd Flanders is proud to offer a wide variety of fabrics, including our Lloyd Flanders in-stock swatchbook fabrics from InsideOut®, Outdura®, Recacril®, Revolution Performance Fabrics™, Sunbelievable®, and Sunbrella®.

Explore the range of colors, patterns and textures available to dress your Lloyd Flanders furniture.

.jpg)

.jpg)

.jpg)